All double edge razor blades are the same size right? Nope.

With over a decade of safety razor design experience we've learned a few things, and one of the biggest is that double edge blades vary in dimension.

Purchasing a precision CNC machined razor that positions the blade inaccurately is like filling a race car with low octane fuel. Why bother!

First let's talk about precision. The average thickness of a human hair is 0.004"/0.10mm. In machinist terms we call this 'four thousandths'.

A CNC machine can easily maintain tolerances of a single thousandth. That's a human hair split four times! That's really accurate.

But, double edge razor blades aren't accurate at all. Everyday Shaving maintains a spreadsheet with measurements from over 400 different razor blades and 150 different brands collected over the past 10 years.

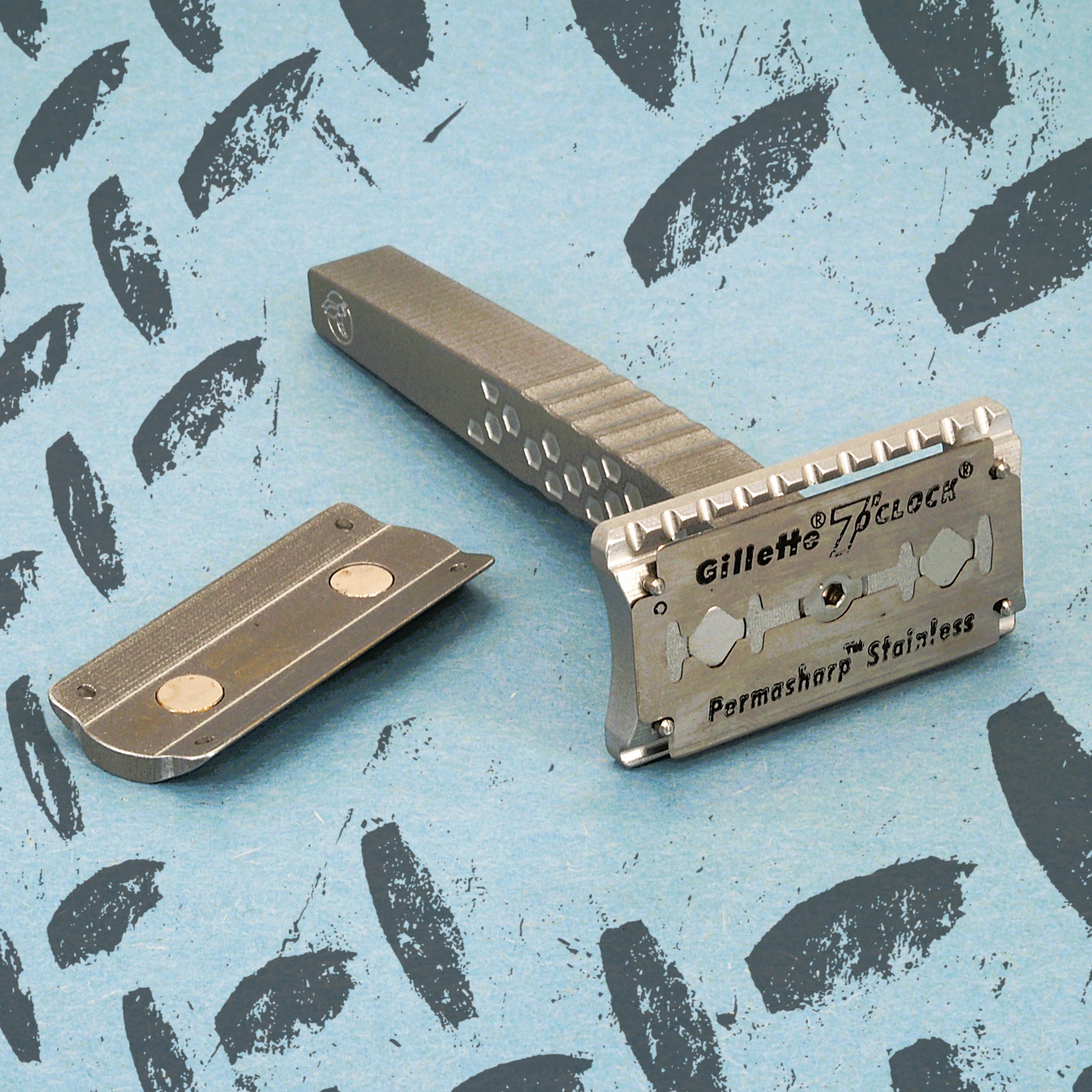

Most safety razors fix the blade using the central cutout of the blade. Dimensions A,B, and C from our photo.

- Dimension A; blade posts diameter varies by 0.006"/0.15mm

- Dimension B; blade bar length varies by 0.015"/0.38mm

- Dimension C; blade bar width varies by 0.005"/0.13mm

We position our four blade alignment pins on the outside of the blade adjacent to the blade tabs. Dimension F in our photo. This dimension only varies by 0.002"/0.05mm.

Dimension E, which is the cutting edge length varies by 0.005"/0.13mm. Our alignment pins have been positioned to accommodate the longest blades currently on the market.

Our positioning method is the most accurate method of locating a double edge blade while accommodating 150 different blade options.

Lastly, Dimension D is the measurement between the cutting edges. This varies by 0.008"/0.20mm. So, for any given safety razor the blade exposure changes based on what blade you choose.